Buster Of Complex

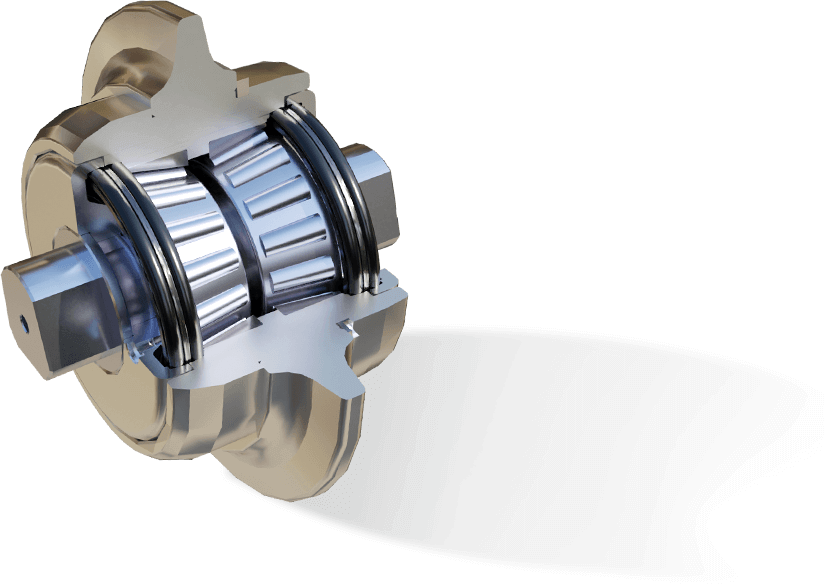

Disc Cutters

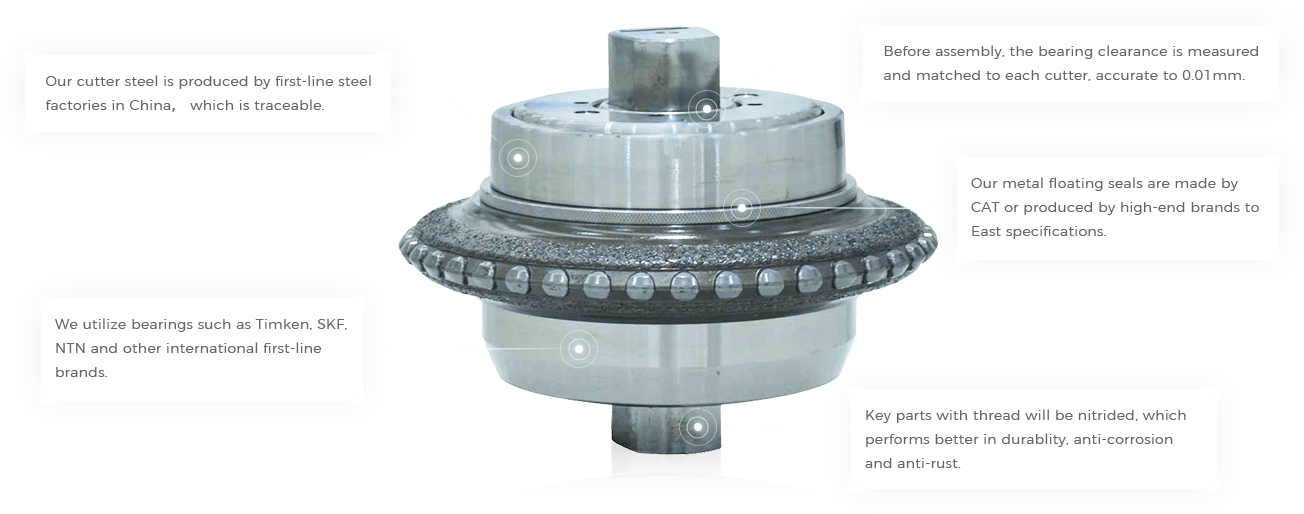

Our cutters range from 15 to 20 inches in diameter, and include common disc cutter and TCI disc cutters based on different rings. We focus on controlling the details from design, material, process, heat treating to assembly to ensure stable & reliable quality of each cutter. Through use and comparison by numerous users, our cutters are standoutwith the lowest damage rate in eccentric wear, oil leak, broken ring and other problems. Moreover, our continued investment in R&D and equipment each year enhances the cutter’s life steadily.

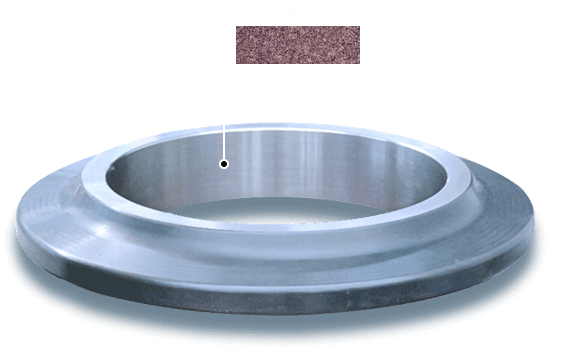

CUTTER RING:

Artworks with strong toughness and wear resistance

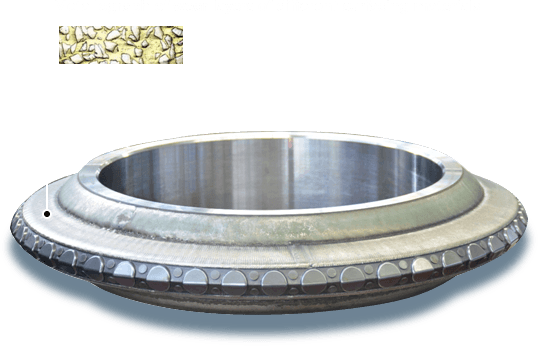

CUTTER RING:

Artworks with strong toughness and wear resistance

We work jointly with well-known steel mills on R&D to control every detail related to smelting, forging and heat treating. Compared with the products from other manufacturers, our cutters have higher toughness and wear resistance under the same hardness. We never stop R&D in cutter materials and processes on the way to improve the cutter’s performance. Currently, we have four materials with intellectual property right adaptive for different formations and construction parameters.

Applicable for ultra-long boring in soft, medium hard (≤120MPa) or high abrasion formations with low impact. Recommended linear speed for the ring: ≤65m/min. We provide this type of ring with wear layer of two processes to ensure a longer service life: cost effective wear layer of crushed WC particles and PAW wear layer with better performance (various powders can be used).

- Material:ESTY001Hardness (HRC):57-60Toughness:Wear resistance:Applicable formations:Applicable for medium hard rock, bedrock protrusions with average impact and uneven formations.

- Material:ESTY002Hardness (HRC):60-62Toughness:Wear resistance:Applicable formations:Applicable for smooth and uniform high hard rock formation with less crack or various highly abrasive formations.

- Material:ESTY003Hardness (HRC):60-62Toughness:Wear resistance:Applicable formations:Applicable for extra hard rock formation with less crack and low impact or various extra highly abrasive formations.

- Material:ESTY004Hardness (HRC):56-58Toughness:Wear resistance:Applicable formations:Applicable for formations with extra high impact such as bedrock protrusions, uneven rock, karst caves and boulders.

SHAFT AND RETAINER

Steel comes from domestic first-line steel mills, with uniform and stable structure composition. Quenched and tempered at high temperature with high-end heat treatment equipment. Finished with high precision CNC equipment. All shafts and retainers with thread are nitrided for anti-corrosion and durablity. One-by-one inspection is adopted for key dimensions.

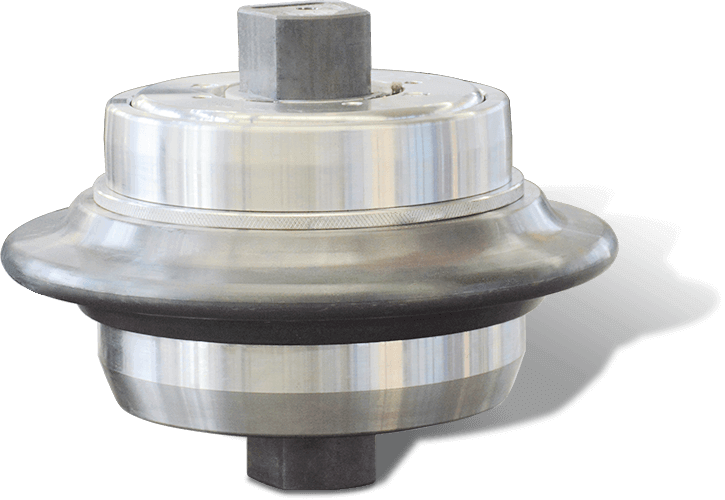

HUB

1. Steel comes from domestic first-line steel mills, with uniform and stable structure composition.

2, Quenched and tempered at high temperature with high-end heat treatment equipment.

3, Finished with high precision CNC equipment.

4, Go through strengthening treatment such as welding wear-resisting layer, surface high frequency, carburizing and so on.

5. One-by-one inspection is adopted for key dimensions.

Hub after quenching and tempering

Surface high freqnency after quenching and tempering

BEARING

The quality of bearing is very important for the quality of cutters. Bearings of EAST cutters are purchased from international first-line brands.

EAST DISC CUTTER