Foshan-Dongguan Inter-city FGZH-Bid No.3 Project

Date:

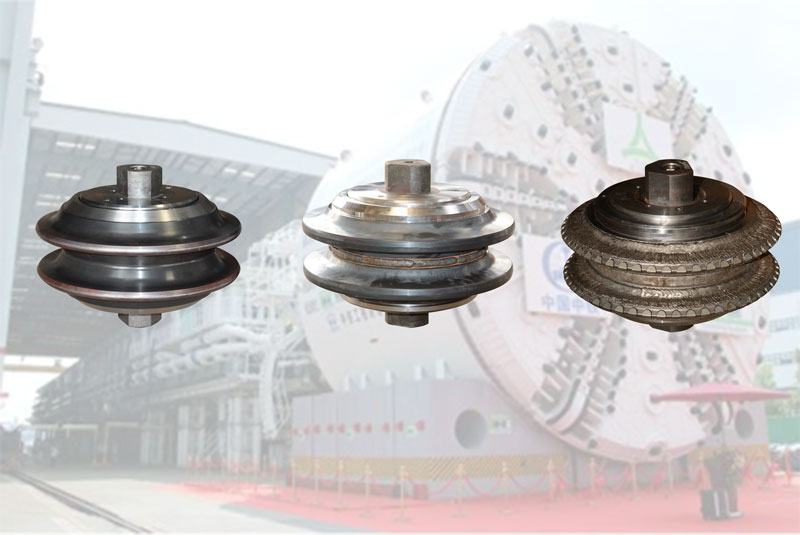

This project is the most challenging large diameter TBM project we are involved in, the formation of which is mostly sandstone the wear on cutters is large. There are many soft and hard uneven sections and many rock fracture zones. The pressure is large, and the maximum water pressure reaches 7 bar or more. The above points bring challenges to the performance of cutters in wear resistance, impact resistance, internal and external pressure balance and the stability of the overall life of the disc cutter. Since the cooperation with the project in March 2017, through trial and improvement of the cutters with the project leader, from the monoblock disc cutter →split disc cutter → monoblock disc cutter with carbide teeth to split disc cutter with carbide teeth. The cutter style has been basically finalized, standardized, and achieved considerable results. Take the gauge disc cutter as an example, the life of the cutter has increased from the initial 20-30 rings to more than 70 rings. The front disc cutter around the center has a life of about 150 rings.

User Test Certificate

Foshan-Dongguan Inter-city FGZH-Bid No.3 Project was undertaken by China Railway Tunnel Group Co., Ltd. It runs from Shilou Town, Panyu District of Guangzhou City, undercrossing Shiziyang of Zhujiang River and to Mayong Town of Dongguan City, with the full length of 6476.4 meters. Of it, the TBM tunnel is 4900 meters long with the largest buried depth of 64 meters and the water depth of 17 meters. The project used a slurry balanced TBM with an excavation diameter of 13.61 meters and of which the cutters can be replaced at normal pressure. Configuration of the cutterhead: 35 19-inch double-blade integral cutters and 48 scrapers both replaceable at normal pressure.

The TBM tunnel requires the segments of 2450 rings to be assembled. When the excavation reached 481 rings, 19-inch double-blade split cutters of East were installed for test.

As for the formation of this tunnel section, about one meter on the top of the tunnel is intensely weathered quartz sandstone and the rest is weakly weathered quartz sandstone with the burial depth of 38-40 meters. In the field test, the 19-inch double-blade split cutters of East worked well with no abnormal conditions. They have wear resistance better than other like products and can bear water pressure of nearly 5.5 kilograms. East improved the design of double blade integral cutters and produced double blade split cutters, enhancing the cutter’s recycle rate and bringing down the cost. It laid a solid foundation for the application of 19-inch double blade split cutters in the complex formations of Shiziyang Tunnel.

China Railway Tunnel Group Co., Ltd

Management Department of Foshan-Dongguan Inter-city FGZH-Bid No.3 Project

January 16, 2018