Dalian Metro Line 5 Bid No.4

Date:

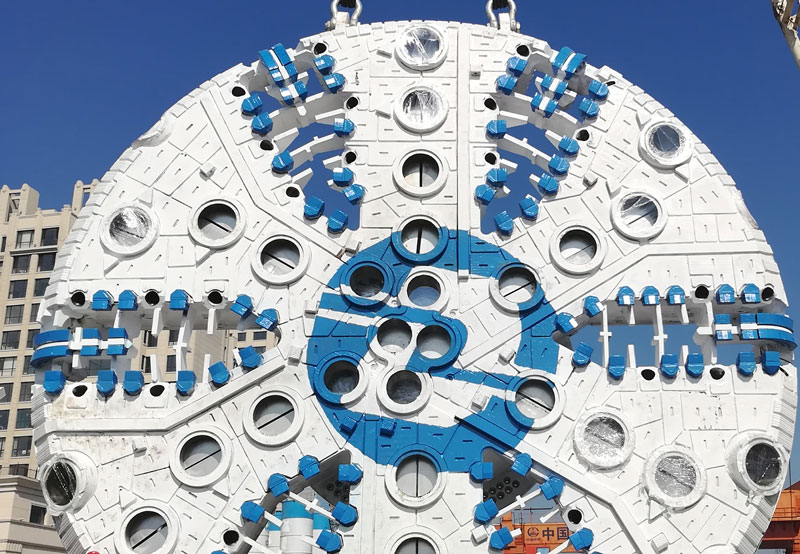

1.Machine: CREG, 12.26m, Atmospheric Slurry TBM.

2. The front section of the TBM excavation area is dolomite (already excavated), with a lot of karst caves. The latter part is slate (up to 120MPa), with several diabase fracture zones in the middle.

3. Main issues: The uneven surface of the face, uneven hardness and softness, causes severe damage to the cutter ring.

4.Measures:

Due to the large number of karst caves and well-developed fissures, the disc cutter is vibrated and impacted, leading to chipping and partial wear of the cutter ring. Consider improving this situation in several ways:

Project exploration summary, improve the tunneling parameters.

Use gradient hardness cutter ring, 25mm and open the edge.

Use impact-resistant cutter ring with blunt teeth.

5.Effects:

★ It is a gradient hardness cutter ring. Although some of the cutter rings have eccentric wear and local chipping, there is almost no cutter ring fracture on the disc cutter.

★ The rock strength of the existing slate and diabase section is high, and the tunneling efficiency of the TCI cutter ring is low. The cutter ring is replaced with a gradient hardness common steel cutter ring.

★ When the heavy-duty carbide teeth cutter ring (without wear layer) is advanced into 26 rings, no abnormal damage is found in the detection cutter, and the amount of cutter wear is small.

Problems with other accessories:

The crushing problem of the cutter housing is serious. After crushing, the mounting surface of the disc cutter cannot fit well, resulting in increased vibration of the disc cutter and further damage to the disc cutter.

Summary: After the cutter housing is crushed, it must be replaced or repaired in time. Otherwise, the small loss will not be worth the loss. Our company provided high-hardness cutter housing for this project. The surface has been specially treated to reach HRC55 or higher. More than 1,000 meters have been used in the project.

User: Urban Rail Transit Engineering Co., Ltd of China Railway First Group Co., Ltd Dalian Metro Line 5 Bid No.4

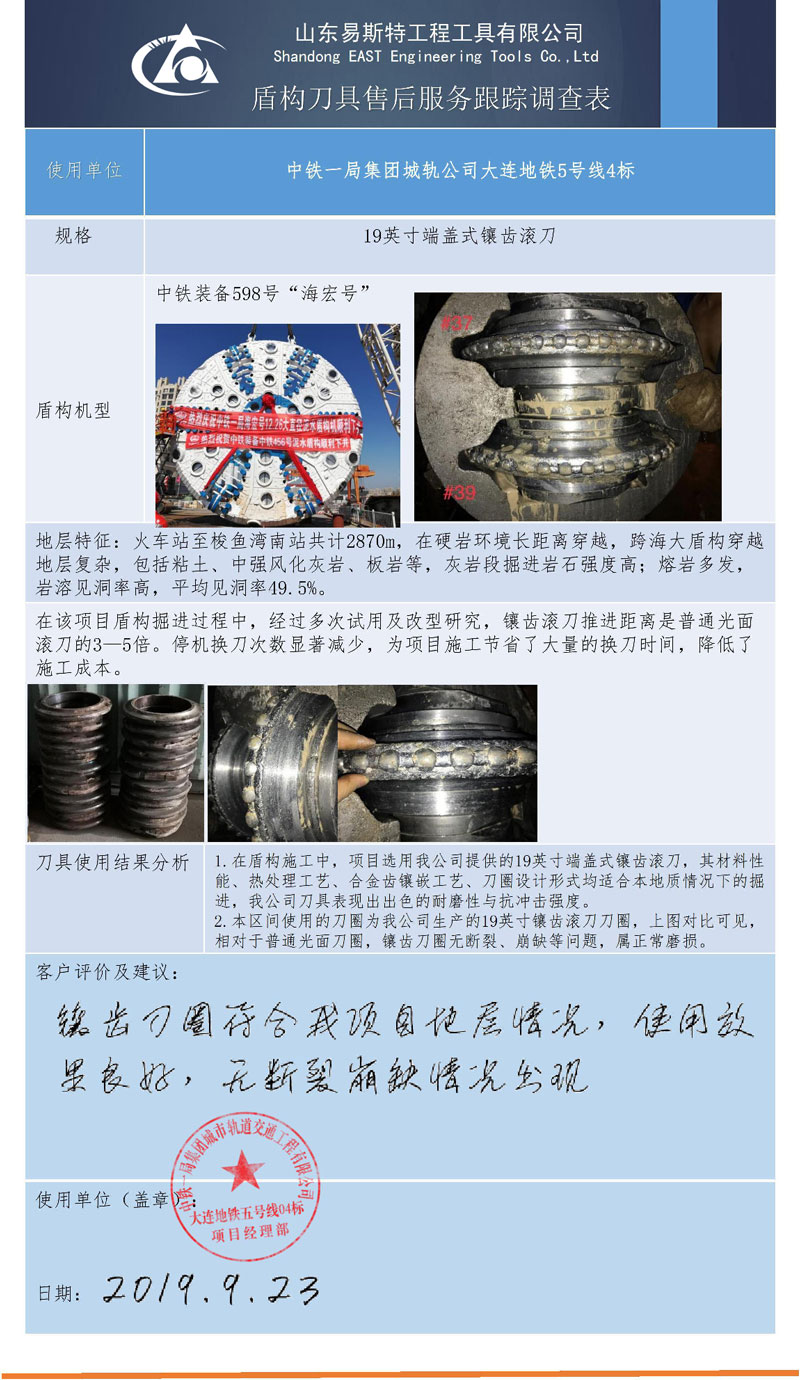

Specification: 19-inch end shield-type TCI disc cutters

TBM model: CREG No.598 “Haihong”

Formation features: The section from Dalian Railway Station to Suoyuwan South Station is 2870 meters long. It requires long distance boring in hard rocks. The cross-sea TBM crosses through complex formations containing clay, moderately weathered limestone, and slate. The lava section has high UCS. Karsts are common with high cave rate, averagely 49.5%.

During TBM boring of the project, after tests and modifications for many times, the advancing distance of TCI disc cutters is 3-5 times of common smooth cutters. The times to stop for cutter replacement are reduced significantly, saving a lot of time on cutter replacement, and reducing the construction cost.

Result analysis:

1. During TBM construction, the project used 19-inch end shield-type TCI disc cutters provided by our company. Their material performance, heat treating process, carbide gear inlay process and ring design pattern are applicable for boring in the geological conditions of the project. Our cutters represent outstanding wear resistance and impact strength.

2. The rings used in the interval are 19-inch TCI disc cutters rings produced by our company. Seen from the above figure, compared with common smooth rings, our TCI disc cutters rings had no burst or rupture and were in normal wear.

Comments and advices from the customer: TCI disc cutters rings are applicable for the formation conditions of our project. They showed out excellent effects with no burst or rupture.

Date: September 23, 2019